Talk to us

08045804604

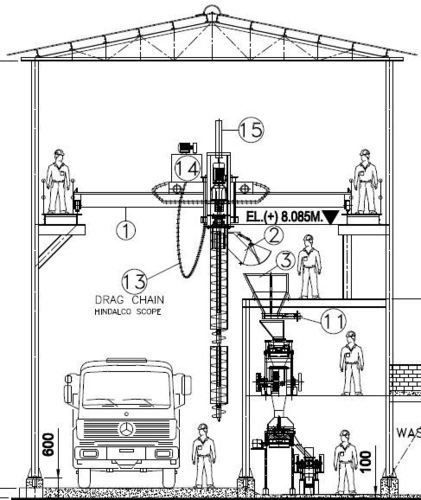

The Stationary Auger System is basically a vertically-oriented section of screw method which rotates within a particular pipe. The bottom section will have a wear resistant cutting tip that helps the subject get loosened and can be collected in that cylindrical hollow section and sampled. Materials then travel up the Auger Spool and the desired quantity gets collected. If the full auger increment has to be collected, the material will be discharged from spool to the desired bin. If the auger increment is to be split, the material passes from the top of the Auger tube and through a fixed splitter where the rejection portion falls back into the truck or rail wagon.

Once the Auger increment being collected in the Spool, the auger is maneuvered to a sample bin. There could be multiple bins for the collection of designated samples which again can be sent for further subsequent sample processing with the help of the primary conveyor and primary crusher for size reduction and may be for secondary conveying with further crushing with rejection handling and sample packaging in small quantity for laboratory processing.

Price:

Price 150000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : 18 months

Equipment Type : Sampling system

Condition : New

Usage : For Coal handling Plant, Cement Plant,Power Plant, Mineral Plant,washery etcs,Mines

Price 500000 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : 1 YR

Equipment Type : Fabricated Item

Condition : New

Usage : For Coal handling Plant, Cement Plant,Power Plant, Mineral Plant,washery etcs,Mines

Price 5000000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 12 months from the date of commissioning

Equipment Type : Mobile Auger Sampler

Condition : New

Usage : Industrial

Price 300000 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : Yes

Equipment Type : Belt End Sampler

Condition : New

Usage : Industrial