Talk to us

08045804604

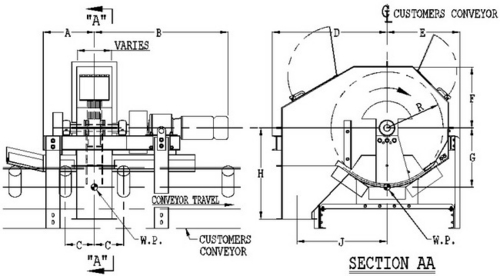

Leveraging on our rich industry expertise, we have been able to manufacture, export and supply Automatic Coal Samplers. These samplers are manufactured in accordance with stated requirements of our valued patrons and in compliance with set norms and regulations of this domain. We have been offering these samplers in both manual as well as PLC operations with total moisture adaptability. Our offered samplers are used in various industry applications with adjustable and non-adjustable dividing ratios. Some striking features of our offered Automatic Coal Sampler are as follows:

Optimum performance

Minimum maintenance

Rust resistant

Easy to operate

Other Details:

APPLICATION: Automatic Coal Sampler

INDUSTRY: Coal, Coke, Dolomite, Limestone, Utilities (Power Plants)

PRODUCT: Electro-Mechanical Sampler

Price:

Price 500000 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : 1 YR

Condition : New

Usage : For Coal handling Plant, Cement Plant,Power Plant, Mineral Plant,washery etcs,Mines

Equipment Type : Fabricated Item

Price 5000000 INR / Set

Minimum Order Quantity : 1 Set

Warranty : 12 months from the date of commissioning

Condition : New

Price 5000000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 12 months from the date of commissioning

Condition : New

Usage : Industrial

Equipment Type : Mobile Auger Sampler

Price 300000 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : Yes

Condition : New

Usage : Industrial

Equipment Type : Belt End Sampler