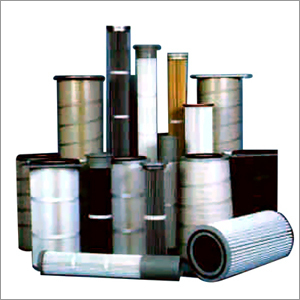

About Cartridge Filter Elements

Founded in the year 1985, ours is one of the most renowned organisations engaged in manufacturing, exporting and supplying a comprehensive range of high-quality Cartridge Filter Elements. They are made available to our clients at the best market price and that too within a pre-defined time frame. These elements are manufactured using high dirt-holding capacity and continuous low-pressure loss. Our offerings are quality checked at various levels of manufacturing so as to ensure that only the best is delivered to clients.

Specifications:

Available in various microns

Used to filter liquids

Thermally prepared

Filter gases

Superior Filtration with Robust MaterialsCartridge Filter Elements are manufactured using Polypropylene (PP), Stainless Steel, or Synthetic Fiber, offering the right balance of durability and compatibility for air, gas, and liquid filtration in demanding environments. These robust materials contribute to corrosion resistance as well as high dirt holding capability, making them suitable for a wide range of industrial and HVAC applications.

Versatile and Adaptable ApplicationWhether you need to filter air, gas, or liquids for HVAC systems or specific industrial processes, these cartridge filter elements are designed for maximum adaptability. With housing-mounted installation and end cap, open both ends, or closed-one-end connections, they seamlessly fit existing filtration setups, ensuring smooth integration and optimal performance.

Effortless Maintenance and Energy EfficiencyDesigned for manual operation, these cartridge filters are easy to replace and clean, promoting longer operational life. Their washable feature reduces consumable costs and environmental impact. Operating without additional energy consumption and generating low noise, they deliver high efficiency and cost-effectiveness, even under high-humidity conditions up to 95%.

FAQs of Cartridge Filter Elements:

Q: How are the cartridge filter elements installed in existing filtration systems?

A: The cartridge filter elements are designed for housing-mounted installation and support various connectivity types, including end cap, open both ends, or closed-one-end configurations. This adaptability enables seamless integration into a wide range of filtration systems for air, gas, or liquid applications.

Q: What materials are available for these cartridge filters and how do I choose the right one?

A: The filters are available in Polypropylene (PP), Stainless Steel, and Synthetic Fiber. Polypropylene is ideal for chemical resistance and general liquid filtration, Stainless Steel suits high-temperature or corrosive environments, while Synthetic Fiber balances efficiency for fine dust or special gas applications.

Q: When should the cartridge filter element be replaced or cleaned?

A: Replacement or cleaning frequency depends on the contamination level and operating conditions. Typically, filters should be checked periodically and cleaned if washable, or replaced if performance drops (pressure increase, reduced output, or visible dirt accumulation). Regular maintenance ensures consistent filtration efficiency.

Q: Where can these filter elements be used most effectively?

A: They are highly effective in HVAC systems, industrial process filtration, and air or liquid purification processes. Their compatibility with high humidity, wide pressure ranges, and high efficiency (up to 99%) make them suitable for various industries across India.

Q: What is the process for maintaining these cartridge filters?

A: Maintenance involves removing the filter element from its housing, washing it if its of the washable type, or replacing it if necessary. Regular maintenance is straightforward due to the manual control system and easy-to-replace design, ensuring sustained efficiency over time.

Q: How do these filters benefit industrial operations or HVAC systems?

A: These filters provide high dust removal efficiency (up to 99%), reduce maintenance downtime due to their easy cleaning and replacement, and help maintain air and liquid quality. Their corrosion resistance and low energy consumption further enhance their operational benefits in industrial environments.